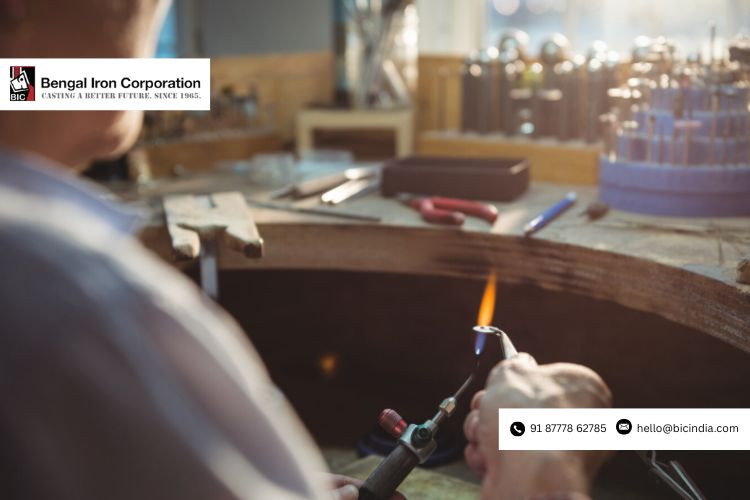

Ever wondered why some industrial components last for decades while others fail too soon? The secret, quite often, lies in the precision and purity of SG iron castings. As industries scale and expectations rise, finding a trusted

SG Iron Castings Manufacturer has become more crucial than ever.

In fact, many modern OEMs quietly depend on a small group of highly reliable foundries—companies that combine metallurgy, engineering, and craftsmanship to produce components that survive heavy loads, harsh weather, and years of wear.

Why SG Iron Castings Matter More Than Ever

SG (Spheroidal Graphite) iron, sometimes called ductile iron, has earned its reputation for toughness. Unlike traditional cast iron, SG iron features nodular graphite structures, making it far more resistant to impact and fatigue. According to data from the American Foundry Society (afsinc.org), ductile iron accounts for nearly half of North America’s total castings due to its strength-to-cost advantage.

Top SG Iron Casting Companies Setting Industry Benchmarks

Here are the standout players known for quality, reliability, and consistent innovation:

1. Magna Foundries

Magna blends old-school metallurgy with cutting-edge testing labs. Their components are widely used in automotive and agricultural machinery, known for dimensional accuracy and fatigue resistance.

2. Ferrotech Global

This firm focuses on high-precision SG iron parts for construction, valve systems, and engineering applications. Their machining capabilities make them a go-to partner for OEMs demanding tight tolerances.

3. Prime Ductile Industries

With a reputation for robust quality assurance, Prime Ductile supplies components trusted in heavy-duty applications like railways, municipal infrastructure, and heavy engineering.

Mid-Section Focus: Role of Trusted Manufacturers

Choosing the rightDuctile Iron Castings Manufacturer is not merely about checking certifications—it’s about ensuring dependable performance for years. The best foundries combine metallurgy expertise with automation, smart molding, and third-party testing.

Qualities That Distinguish Top Foundries

- Advanced molding techniques such as DISA lines or green sand automation.

- On-site metallurgical labs for microstructure analysis.

- Heat treatment and machining facilities under one roof.

- Certifications like ISO 9001, 14001, and specific industry approvals.

Some foundries also excel in specialized verticals, such as producing high-durability Agricultural Castings for farming equipment or developing components compliant with IS 3989 for water supply systems.

How SG Iron Benefits Modern Industries

From automotive knuckles to municipal manhole covers, SG iron has become indispensable across sectors. Industries choose it because it offers a sweet spot between tensile strength, ductility, and cost-effectiveness.

Key Advantages at a Glance

- Impact Resistance: Ideal for dynamic load components.

- Superior Elongation: Reduces cracking under stress.

- Cost-Optimized: Cheaper than steel yet tough enough for heavy-duty use.

- Versatile Applications: From transmission housings to pump casings.

Additional helpful keywords: ductile iron components, industrial foundry services, precision metal casting.

Frequently Asked Questions

1. What makes SG iron better than traditional cast iron?

SG iron contains spheroidal graphite, giving it exceptional ductility and toughness compared to the brittle nature of grey cast iron.

2. Which industries use SG iron castings the most?

Automotive, construction, water supply, railways, and heavy engineering are the top users due to the material’s strength and reliability.

3. How do I choose a reliable SG iron casting company?

Look for certifications, in-house testing labs, machining capabilities, and proven industry partnerships. Experience with large-scale OEMs is also a plus.

4. Are SG iron castings cost-effective for long-term use?

Yes. Their durability significantly reduces replacement and maintenance costs, making them a smart long-term investment.

Also Read: Why Sealing Access Points is Essential for Groundwater Safety

Final Thoughts

The best SG iron casting companies don’t just deliver components—they deliver long-term dependability. As industries scale and machinery demands grow, partnering with a trusted foundry becomes a strategic advantage rather than a mere procurement choice.

Blog Development Credits:

This blog was conceptualized and developed by Bengal Iron Corporation, researched using advanced AI tools, and finalized with SEO and optimization enhancements for accuracy and readability.